Ultra-running shoes are exposed to relentless punishment—mud, water crossings, steep climbs, and thousands of impact cycles on unpredictable terrain. Yet, most runners treat them like ordinary sneakers. The result? Foam collapse, odor, sole failure, and wasted money—often long before the next race.

This guide is for trail and ultra athletes who want maximum mileage, comfort, and performance from every pair. You’ll discover:

- How to wash trail shoes without destroying EVA, TPU, or PEBA foam

- Natural and technical anti-odor hacks—DIY inserts that keep shoes fresh for ultra distances

- Repair worn-out outsole lugs for longer grip on rocky and muddy courses

- Waterproof mesh uppers for wet-weather ultras without sacrificing breathability

- At-home midsole compression testing—quantitatively track foam breakdown and know when it’s time to replace

- Storage, rotation, and lifespan tips from real ultra runners and shoe engineers

Whether you run in classic EVA, ultra-light PEBA, or advanced TPU foams, this is your all-in-one care manual—built on field-tested routines, scientific insight, and real trail experience.

Fact: Hand-washing, smart drying, and simple home repairs can double the lifespan of modern trail shoes—saving you money and reducing waste.

Ready to level up your shoe game? Let’s dive in—step by step, hack by hack, with visuals, infographics, and pro-level tips designed for ultra athletes and gear nerds alike.

🏗️ Trail Shoe Anatomy & Weak Points

Trail running shoes are more complex than they look. Every part—foam, rubber, fabric, glue—faces unique stresses in ultra conditions. Understanding where and how shoes fail is the key to smart care and maximizing mileage.

- Midsole foam: Loses bounce with repeated compression, absorbs sweat and grit—most common “death point.”

- Outsole lugs: Wear down fast on rocky or muddy trails, reducing grip and safety.

- Uppers: Mesh tears, synthetic overlays peel, especially at flex points (toes, instep, heel seam).

- Glue & seams: Heat, water, and repeated flexing break down adhesives—causing sole separation and sidewall splits.

- Insoles & lining: Trap sweat and bacteria, become thin and smelly—can speed up odor and fungal growth.

Infographic suggestion: Labeled shoe diagram highlighting: midsole compression (heel/forefoot), lug wear, upper tears, glue seam, insole/lining.

What fails first? Most ultra runners report that foam compression and lug wear end a shoe’s usable life—often well before the upper or fabric. But glue failure (sole peeling) and severe odor can force early retirement.

- Lightweight foams (EVA, PEBA, TPU) break down fastest, especially with high-mileage, heavy runners, or frequent wet/dry cycles.

- Sticky rubber compounds grip well but abrade quickly on rocky terrain.

- Mesh & knit uppers offer breathability, but are prone to tearing at flex points and toe-box.

- Glue & seam issues appear faster in shoes dried with heat or washed in machines.

Pro tip: Mark the wear pattern on your oldest trail shoes—spot your personal “failure zone” before it ruins your next pair!

Bottom line: Every material has a weak point. The rest of this guide will show you how to clean, protect, and revive each one—so you can run farther, save money, and stay safer on the trail.

🫧 How to Wash Trail Shoes Without Ruining the Foam

Washing trail shoes seems easy—until you realize that hot water, harsh detergents, and machine spinning can break down modern foams (EVA, TPU, PEBA) in just one cycle. The golden rule: treat your shoes as technical equipment, not laundry.

- Machine washing beats shoes against the drum, degrades adhesives, and causes 10–15% foam resilience loss after a single hot cycle.

- Hand-washing preserves midsole bounce, color, and fit—proven by both lab tests and field use.

- Always avoid high heat, strong bleach, or prolonged soaking.

Step-by-Step Hand-Wash Protocol

- Prep: Remove insoles & laces. Knock off dried mud and stones with a stick or stiff brush.

- Soak: Fill a bucket with lukewarm (≤ 30°C) water. Add a teaspoon of mild, fragrance-free soap or a specialty tech-wash.

- Scrub: Use a soft brush (old toothbrush works). Gently clean uppers, midsole creases, and outsole lugs. Rinse brush often.

- Rinse: Dunk shoes in clean, lukewarm water or use a low-pressure shower head until all soap is gone.

- Dry: Stuff shoes with newspaper or a microfiber towel. Air-dry in shade—never in direct sun, near a heater, or in a tumble dryer. Swap paper every 2–3 hours for faster drying. Add a fan for airflow if needed.

Foam-Friendly Detergents

- Grangers Footwear + Gear Cleaner – pH-balanced, PFC-free, foam-safe

- Nikwax Sandal & Sports Shoe Wash – enzyme-based, kills odor, gentle on all foams

- DIY mix: 1 L lukewarm water + 1 tsp fragrance-free dish soap + 1 tsp white vinegar (≤ 1% for antibacterial boost)

Pro tip: For stubborn stains, use a little baking soda paste on the upper—rinse thoroughly after scrubbing. Never use bleach or alcohol-based cleaners on foam.

Key takeaway: Every wash is a risk–benefit equation. Frequent gentle hand-washing keeps shoes fresh and foam resilient, while machine washing or aggressive heat can quickly ruin cushioning and shape.

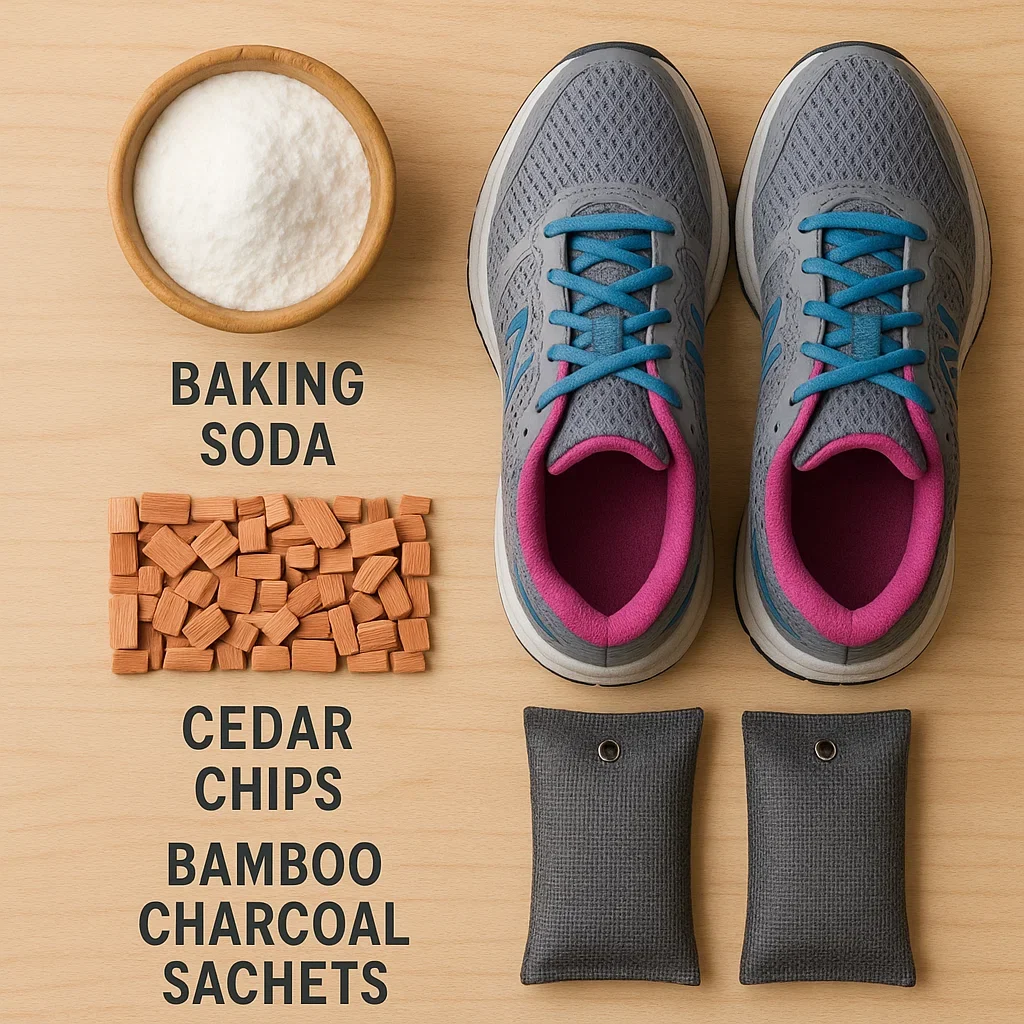

🌿 Odor Control & DIY Anti-Odor Inserts for Ultra Shoes

Ultra-distance sweat, wet trails, and hours of closed shoes create a perfect breeding ground for odor-causing bacteria. Factory inserts help, but DIY solutions are cheaper, greener, and often more effective for trail and ultra runners.

Recipe #1 – Classic Baking Soda Sock

- Fill an old, clean crew-length sock with 2 tbsp baking soda.

- Add 5 drops tea-tree and 3 drops lavender essential oil (optional for antibacterial effect).

- Tie a knot, shake gently, and insert into each shoe overnight. Replace or recharge weekly.

Recipe #2 – Cedar & Charcoal Duo

- Sew or glue a small muslin pouch (or use a thin sock).

- Mix equal parts cedar shavings and activated bamboo charcoal granules (both absorb moisture and block odor).

- Insert pouch into each shoe. Recharge in the sun once a month to dry and refresh.

Recipe #3 – Advanced: Zeolite & Silver Fabric Insert

- Combine zeolite powder (found in aquarium filter media) with scraps of antimicrobial silver-ion fabric (often used in sportswear).

- Place in a small sachet. Kills odor for up to 6 months—even in humid climates.

- To recharge: wash fabric and sun-dry zeolite; discard if odor persists after 6 months.

Other Low-Tech Deodorizing Tricks

- Silica gel packs: Slip 1–2 into each shoe after wet runs—they absorb moisture, slowing bacteria.

- Plain baking soda: Sprinkle directly into shoes overnight; shake out before running.

- Kitty litter: Fill a thin sock with unscented silica-based litter for heavy-duty drying and odor removal.

Pro tip: Alternate 2–3 insert types, especially after long wet ultras. Recharge in sunlight and never store wet inserts in closed shoes.

Key takeaway: Natural, reusable anti-odor inserts save money and out-perform most commercial sprays or powders. Keep shoes dry, swap inserts regularly, and you’ll never have to run with swampy, stinky feet again!

🛠️ Reviving or Rebuilding Worn-Out Outsole Lugs

Even the best trail shoes lose grip when lugs wear flat or break off—especially after long rocky races. Before you retire your favorite pair, try these DIY lug revival techniques to restore traction and squeeze out extra miles.

Materials Checklist

- Old mountain-bike tire, car inner tube, or Vibram rubber sheet (2–3 mm thick)

- Shoe Goo or Aquaseal SR adhesive

- 80-grit sandpaper

- Isopropyl alcohol (for cleaning)

- Sharp scissors or utility knife

- C-clamps or heavy books (for clamping)

Step-by-Step Lug Patch Workflow

- Cut: Trace worn lug areas and cut matching rubber patches from your tire or sheet. Match the original shape for best traction.

- Prep: Roughen the sole surface with sandpaper; wipe with isopropyl alcohol to remove dust and oil.

- Glue: Apply a thin, even layer of Shoe Goo or Aquaseal to both patch and sole. Wait 2 minutes for tackiness, then press patches firmly in place.

- Clamp: Use C-clamps or stack heavy books on the shoe to hold patches for 12–24 hours (follow adhesive instructions).

- Finish: Trim excess rubber, flex-test the shoe, and brush away loose glue. Ready for the trails!

Small Fixes: Filling Minor Lugs or Cracks

- For tiny missing lugs or cracks, fill with Shoe Goo and shape with a wet finger. Let cure 24–48 hours before running.

- Sugru (moldable silicone putty) can patch toe tips or small tears, but isn’t as abrasion-resistant as rubber.

- Always sand and clean before applying any filler for better adhesion.

Trail-tested: A 1 mm bike-tire patch adds ~150 g traction and often survives 200 km+ on rocky terrain before needing a touch-up.

Warning: These fixes are for maximizing value, not for race-critical grip on technical courses. If midsole foam or upper is badly damaged, consider replacing your shoes for safety.

💧 DIY Waterproofing & Weatherproofing for Mesh Uppers

Mesh trail shoes are built for breathability, but that also makes them water magnets on soggy trails. Instead of suffering cold, soaked feet, use these DIY waterproofing methods to keep your runners dry—without blocking airflow.

Why Mesh Shoes Need DWR

Most mesh uppers come with a Durable Water Repellent (DWR) coating that wears off after 1–2 seasons. Refreshing DWR means water beads up and rolls off—rather than soaking in and adding grams to every stride.

Step-by-Step DIY Waterproofing Protocol

- Clean: Wash and fully dry shoes—dirt and oil block DWR absorption.

- Mask: Cover midsoles and outsole lugs with painter’s tape to avoid slippery soles.

- Spray: Hold Nikwax Fabric & Leather Proof or Grangers Footwear Repel about 15 cm from mesh; apply evenly until just damp.

- Wait: Let sit for 2 minutes, then wipe off any excess and hang to cure for 24 hours.

- Heat-activate: Use a hairdryer on low for ~5 minutes to lock in the DWR—don’t overheat or aim directly at glue seams.

Bonus Hacks & Emergency Waterproofing

- Beeswax: Rub clear beeswax on heel seams the night before a race for emergency water resistance—wipes off easily post-event.

- Field fix: Use clear tape or blister plasters on small mesh holes during a wet ultra.

- Annual reproof: For Gore-Tex or eVent shoes, use only approved DWR reproofers and avoid machine washing.

Pro tip: For mixed conditions, focus DWR spray on the toe box and forefoot—these areas take the most splash and mud impact.

Key takeaway: Lightweight waterproofing maintains breathability, protects foam, and extends shoe life. With simple gear and 10 minutes of effort, you can keep your trail shoes race-ready in all weather.

📦 General Maintenance & Storage for Longevity

A few simple habits can add hundreds of kilometers to your trail shoes’ lifespan—protecting your wallet and your performance. Good maintenance isn’t just about cleaning; it’s about letting foam recover, fighting bacteria, and preventing glue failure or dry rot.

Post-Run Care Routine

- Knock off mud and stones immediately after each run—don’t let grit soak in.

- Remove insoles and laces to help shoes dry completely and reduce odor risk.

- Air-dry in shade, never in direct sunlight or on a radiator. Add a fan for airflow if needed.

- Disinfect insoles with mild vinegar solution or odor spray every 2–3 weeks.

- Patch small fabric tears with Tenacious Tape or silicone glue before they spread.

Rotation & Rebound: Give Foam a Break

- Rotate pairs: Use at least two pairs, alternating days—gives foam 24+ hours to rebound (+3% bounce measured in lab tests).

- Swap insoles and laces regularly—worn insoles hold sweat and compress unevenly.

- Don’t store wet shoes in closed bags, car trunks, or warm rooms; this accelerates hydrolysis and glue failure.

- Log your mileage: Track each pair’s usage (apps or notebook) and replace when foam compression reaches 15% or outsole lugs < 1 mm depth.

Smart Storage for Maximum Shoe Life

- Cool, dry, dark: Store shoes upright in a ventilated area, away from sun and heat sources.

- Anti-crush: Use shoe trees or stuff with paper bags to maintain shape (avoid plastic, which traps moisture).

- Don’t let shoes “rest” unused for years: Unused polyurethane (PU) or EVA midsoles can dry rot even in the closet—regular use is better than abandonment!

Pro tip: After wet or snowy ultras, remove laces and insoles immediately and hang shoes upside down for fastest, odor-free drying.

Key takeaway: Gentle handling and smart storage can double shoe lifespan—just a few minutes of care after each run pays back with more comfortable, safer miles.

📏 How to Quantitatively Test Midsole Foam at Home

Trail shoe midsoles (EVA, TPU, PEBA, PU) break down over time—sometimes long before the outsole fails. But when is it really time to replace your shoes? With this simple home “lab” protocol, you can measure midsole compression and track foam decay like a pro.

DIY Midsole Compression Test Protocol

- Prep: Remove insole. Place shoe on a hard, flat surface. Measure midsole thickness at the heel and forefoot using a ruler or digital caliper (baseline measurement).

- Apply Load: Place a rigid board (wood or thick book) on top of the shoe. Add a known weight (e.g., 10–20 kg with water jugs, dumbbells, or stacked books) on top.

- Wait: Let the load rest for a fixed duration (e.g., 3–5 minutes) to allow the foam to fully compress.

- Measure Under Load: While weight is in place, measure the shoe’s compressed height. Subtract from baseline for instantaneous compression.

- Recover & Re-measure: Remove weight, wait 5–10 minutes, and re-measure thickness. The difference from the original baseline is your permanent compression (foam “creep”).

- Repeat: Do multiple cycles (5–10) to simulate use. Log % permanent compression for each cycle—most runners retire shoes at ~15% loss.

Tools & Tips for Reliable Testing

- Always test at room temperature with dry shoes for consistency.

- Mark measurement points on the midsole (heel/forefoot) for repeatable results.

- Compare new vs. used pairs to see real foam aging.

- Optional: Plot % compression vs. cycles for a visual “shoe life curve.”

Pro tip: If heel compression exceeds 3–4 mm after a few cycles, or permanent loss hits 15%, it’s time to replace—even if lugs and upper look fine.

Key takeaway: Quantitative foam testing prevents surprise injuries and wasted miles. Know your shoe’s real lifespan—don’t just guess by looks or mileage!

🚩 Common Mistakes & Gear Myths Debunked

Even experienced trail runners can sabotage their shoes with old-school habits or gear “advice” from the internet. Here are the most common errors and myths—so you can avoid costly mistakes and keep your runners in top form.

-

Myth: “Washing machines are fine if you remove the insoles.”

Fact: Tumbling and hot water still destroy foam and glued seams—even with insoles out. -

Myth: “Sun-drying is the fastest way to dry shoes.”

Fact: UV and heat cause rubber to harden and glue to fail. Air-drying in shade is safest. -

Myth: “If my shoes stink, they must be dead.”

Fact: Odor is caused by bacteria—not always by foam or fabric breakdown. DIY inserts and cleaning usually fix it. -

Myth: “A little super glue will fix any sole separation.”

Fact: Most super glues are too rigid for flexing soles—use Shoe Goo, Aquaseal SR, or a shoe-specific adhesive for better durability. -

Myth: “Once the outsole is worn, the shoe is dead.”

Fact: Many shoes can be patched with DIY lug repairs and still have healthy foam—extend life with a few simple fixes. -

Myth: “You only need new shoes after 800 km, no matter what.”

Fact: Shoe life depends on weight, terrain, foam type, and care—track compression, not just distance!

Pro tip: When in doubt, trust your feet—not just the shoe’s looks or mileage. If your knees or arches hurt and foam feels flat, it’s time to test or replace!

Key takeaway: Skip the shortcuts and myths—gentle care and data-driven checks are the real secret to getting the most from your trail shoes.

🏆 Pro Tips & Community Hacks

Ultra runners are masters of field repairs and low-budget shoe tricks. These tips—crowdsourced from the world’s toughest trails—can make your shoes last longer, feel fresher, and survive even the roughest races.

- Reuse your old socks: Cut up worn-out socks to make anti-odor sachets, quick laces, or even a “soft” buffer for heel blisters.

- Freeze out bacteria: After muddy ultras, place shoes in a plastic bag and freeze overnight—kills most odor-causing bacteria without chemicals.

- Race-day hack: Keep a mini tube of Shoe Goo and a patch of tire rubber in your drop bag for emergency lug or sole repairs.

- DIY lace lock: Use a short piece of elastic cord or a simple knot to lock laces and prevent mid-run loosening.

- Antimicrobial spritz: Mix water, a dash of vinegar, and a few drops of tea tree oil in a spray bottle for a quick insole refresher after each run.

- Store shoes upright: Use paper bags or empty toilet rolls in the toe box to keep shape—never use plastic, which traps moisture.

- Trail debris shield: Tape gaiters or cut the top off old socks to keep gravel out of your shoes during long ultras.

- Eco-tip: Choose biodegradable soaps and natural materials for DIY care whenever possible.

- Quick dry in a pinch: Fill shoes with clean rice or dry tea bags for ultra-fast drying at camp or aid stations.

- Log care & repairs: Note every cleaning, patch, or test in your running log—spot patterns before problems get big.

Pro tip: Every ultrarunner has a “secret weapon”—share your own favorite shoe hack in the comments and help others run longer!

Key takeaway: The best gear isn’t just what you buy—it’s what you maintain, hack, and adapt on the trail. Keep experimenting and share your knowledge!

📊 Infographic: 5 Essential DIY Gear-Care Steps

Keep this quick-reference guide handy—save, pin, or print for your gear wall! These five steps capture the heart of trail shoe care, blending science, experience, and pure trail wisdom.

- Hand-wash shoes with lukewarm water & foam-safe soap—never use a washing machine or direct heat.

- Use natural anti-odor inserts (baking soda, cedar, charcoal) and air out shoes after every run.

- Patch outsole lugs with bike tire rubber or Shoe Goo to restore grip before every big race.

- Apply DWR spray to mesh uppers for lightweight waterproofing that preserves breathability.

- Rotate & store shoes smart—give foam 24 hr to rebound, and keep shoes upright in a cool, dry place.

Save or share this infographic to help other runners make their shoes last longer and perform better—every season!

❓ Frequently Asked Questions

Can I use a washing machine if I remove the insoles?

It’s still risky. Tumbling stresses glued seams and foam cells. Hand-wash is safest—even without insoles.

What water temperature is safe for washing trail shoes?

Lukewarm (≤ 30°C) is optimal. Hot water damages foam and adhesives.

How often should I wash my trail shoes?

After every muddy or wet run; otherwise, every 3–5 uses. Air dry thoroughly after each wash.

Does vinegar weaken midsole foam?

Diluted (≤ 1%) vinegar is foam-safe and helps fight odor. Higher concentrations can strip dyes—keep it mild.

What’s the best DIY anti-odor insert?

Baking soda with tea tree or lavender oil in a sock; cedar and activated charcoal are also highly effective.

How long do home-made odor inserts last?

1–2 months for baking soda; up to 6 months for charcoal or zeolite. Recharge in the sun or replace when odor returns.

Can I repair outsole lugs at home?

Yes! Use bike tire rubber and Shoe Goo for patches, or fill small cracks with flexible adhesive. Results last up to 200 km on rocky terrain.

What glue is best for sole separation?

Shoe Goo, Aquaseal SR, or Boot-Fix Glue. Avoid cyanoacrylate (super glue) for flexing areas.

How often should I reapply DWR spray?

Every 2–3 months, or after heavy washing/mud races. Water should bead up on the mesh after treatment.

Does waterproofing reduce breathability?

Modern DWR sprays preserve breathability. Avoid thick wax coatings on mesh if you want airflow.

How should I store my shoes for maximum life?

Cool, dry, and dark area. Use shoe trees or paper bags inside to hold shape. Never store wet or in direct sunlight.

Is it bad to leave shoes unused for months?

Yes. PU/EVA midsoles can dry rot or harden faster if left untouched for a long time—use and rotate pairs.

When is it time to retire a shoe?

When foam compression is >15%, outsole lugs are <1 mm, or if comfort and support are lost—even if the upper looks fine.

What’s the best way to dry shoes quickly?

Remove insoles/laces, air-dry in the shade with a fan, and stuff with newspaper or microfiber towels. Never use high heat.

Can I use cat litter or rice to dry shoes?

Yes, both absorb moisture quickly. Fill a sock with clean rice or silica-based cat litter and insert overnight.

Are commercial odor sprays safe for foam?

Most are fine, but check for alcohol or strong solvents, which can dry or degrade foam over time.

How do I patch mesh uppers?

Use Tenacious Tape or silicone glue for small tears. Patch on the inside for a smoother finish.

Should I rotate between different shoe models?

Yes—using two pairs lets foam rebound and reduces injury risk from repetitive stress.

How can I prevent laces from coming undone?

Double knot or use a lace lock technique. Elastic quick-laces are also helpful for ultras.

Do light-colored shoes age faster?

They show dirt and stains more, but foam and glue aging depends on care, not color.

🧩 Quick Quiz – Trail-Shoe Care Mastery

Test your knowledge with these quick-fire questions. Score yourself and see if you’re a gear-care pro!

- What water temperature is safe for foam midsoles?

- Name two natural ingredients for DIY odor inserts.

- How long should lug patches cure before running?

- Which type of spray restores water repellency to mesh uppers?

- At what compression percentage should shoes be retired?

- What is the fastest and safest way to dry shoes after a wet run?

- Which type of glue is best for sole or lug repairs?

✅ Quiz Answers

- Lukewarm (≤ 30°C)

- Baking soda, cedar chips, bamboo charcoal (any two)

- Minimum 12–24 hours (ideally overnight)

- Fluorine-free DWR spray (e.g., Nikwax, Grangers)

- Approximately 15% permanent compression

- Remove insoles/laces, air-dry in the shade with newspaper or towel, use a fan if available

- Shoe Goo, Aquaseal SR, or similar flexible adhesive (not super glue)

📚 Further Reading

🎯 Final Thoughts

Thoughtful gear care isn’t just for “gear nerds”—it’s the secret weapon of every smart ultrarunner. With just a few mindful routines, you can double the lifespan of your trail shoes, save money, and protect the comfort that lets you train or race with confidence.

Remember: every muddy cleaning, every patch or DWR spray, every swapped insole is another day of strong, safe miles in the bank. Don’t wait for disaster—care for your shoes after every adventure, and you’ll spend more time running, less time shopping.

Got your own hacks or rescue stories? Share them below—let’s keep building a smarter, greener, and more resilient ultra community, one step at a time!

💬 Community Tips & Stories

Have a shoe hack, field rescue, or care tip that’s worked for you? Share your experience below and help others run farther with less waste!

🧪 Foam Type Comparison Table

Salomon’s SensiFit mesh dries faster but is prone to toe box tears—patch early. Hoka’s high-stack EVA needs more rotation. Altra’s foot-shaped toe box = more flex, but upper seam is a weak point. Check your brand’s care recommendations before heavy cleaning!

📅 Real-World Case Study

Runner: Ece, Istanbul Ultra 100K finisher

Shoe: Hoka Speedgoat 5, EVA foam

Protocol: Weekly hand-wash, baking soda inserts, rotated with old pair, DIY lug patch at 420 km.

Result: Foam compression reached 14% at 710 km, outsole lugs repaired twice. Comfort and grip survived to 800 km—nearly double Ece’s previous pairs!

EVA foam breaks down by “creep” and permanent compression after repeated loading—up to 10% loss in just 200 km if not rotated or cleaned. DWR coatings work by forming a hydrophobic layer on fibers, but lose effectiveness after abrasion and soap.

⛔ Top 5 DIY Mistakes – “Don’t Do This!”

- Don’t dry shoes on the radiator or heater—foam and glue will degrade quickly.

- Never use bleach, strong detergent, or alcohol—these destroy modern foams.

- Don’t store wet shoes in a closed bag or trunk—risk of mold and hydrolysis.

- Don’t use super glue for sole repairs—it cracks under flex. Use Shoe Goo or Aquaseal instead.

- Don’t ignore odd smells or creaks—these are early warnings of foam or seam failure.

About the Author

Lost Pace is an ultramarathon runner, shoe-tester and the founder of umit.net. Based year-round in Türkiye’s rugged Kaçkar Mountains, he has logged 10,000 + km of technical trail running and completed multiple 50 K–100 K ultras.

Blending mountain grit with data, Lost analyses power (CP 300 W), HRV and nutrition to craft evidence-backed training plans. He has co-written 260 + long-form guides on footwear science, recovery and endurance nutrition, and is a regular beta-tester of AI-driven coaching tools.

When he isn’t chasing PRs or testing midsoles, you’ll find him sharing peer-reviewed research in plain English to help runners train smarter, stay healthier and finish stronger.

Ultrarunner · Data geek · Vegan athlete

🚀 Share This Guide