I. Introduction:

Ask any group of runners when to replace their shoes, and you’ll likely get a flurry of different answers. Some swear by meticulous mileage tracking, retiring their trainers precisely at the 300, 400, or 500-mile mark. Others go by feel, waiting for that undefinable moment when the shoes just seem “dead.” Then there’s the infamous “300-500 mile rule” (or 500-800 km for metric users) – a guideline so pervasive it’s often quoted as gospel by running stores, websites, and even fellow runners.

But here’s the million-dollar question: In an era of rapidly evolving shoe technology, space-age foams, carbon plates, and sky-high stack heights, does this one-size-fits-all mileage rule still hold up? The short answer, backed by a growing body of research, is a resounding no.

Relying solely on mileage ignores the vast complexity of how running shoes wear out and the incredible diversity of modern footwear. It matters less how far you’ve run and more what happens to the shoe during those miles. Understanding this is crucial, not just for optimizing performance and comfort, but also for navigating the often-murky waters of potential injury risk.

At the heart of this discussion lies the midsole. Think of it as the engine of your running shoe – the critical layer between the outsole (the rubber that hits the road) and the upper (the fabric holding your foot). This unassuming layer of foam is responsible for the magic: cushioning your landing, providing stability, absorbing shock, and ideally, giving you a little energy boost with each step. Consequently, the lifespan of your running shoe is intrinsically linked to the lifespan of its midsole foam. When the midsole breaks down, the shoe’s core functionality degrades.

This comprehensive guide aims to move beyond anecdotal advice and arbitrary mileage counts. We will delve deep into the running shoe wear science, exploring exactly how and why your shoes break down, with a particular focus on the crucial process of running shoe midsole degradation. We’ll compare the different types of foams powering modern running shoes, examining how their unique properties influence their durability. We will thoroughly debunk the mileage myth and explore the numerous factors affecting running shoe life – from your individual characteristics to the shoes’ design.

Furthermore, we’ll look at how worn shoes can subtly alter your running biomechanics and critically examine the running shoe replacement evidence concerning the hotly debated link between old shoes and injuries. Finally, and perhaps most importantly, we’ll provide practical, evidence-based guidance on how to assess running shoe wear, empowering you to make informed decisions about when it’s truly time for a new pair. Get ready to become a smarter, more informed runner.

II. The Science of Running Shoe Breakdown: Why Your Trusty Trainers Don’t Last Forever

Ever wondered why that once-bouncy pair of shoes now feels flat and unresponsive? It’s not just in your head. Running shoes undergo a tangible, measurable process of degradation with every single step. Understanding the running shoe wear science is the first step to making smarter replacement choices.

A. The Relentless Impact: Death by a Thousand Steps

Running is, by its very nature, a high-impact activity. Each time your foot strikes the ground, it generates a force equivalent to roughly 1.5 to 3 times your body weight. Your running shoes are designed to manage these forces, primarily through the cushioning properties of the midsole foam.

Now, consider that a typical runner takes somewhere between 1,200 and 1,500 steps per mile (or 750-930 steps per kilometer). Over the course of a 5-mile run, that’s 6,000 to 7,500 impacts your shoes have to absorb. Multiply that over weeks and months, and you’re talking about hundreds of thousands, even millions, of loading cycles. This relentless, cumulative stress is the primary driver of running shoe midsole degradation. The foam simply gets tired.

B. Midsole Material Fatigue: What Happens Inside the Foam?

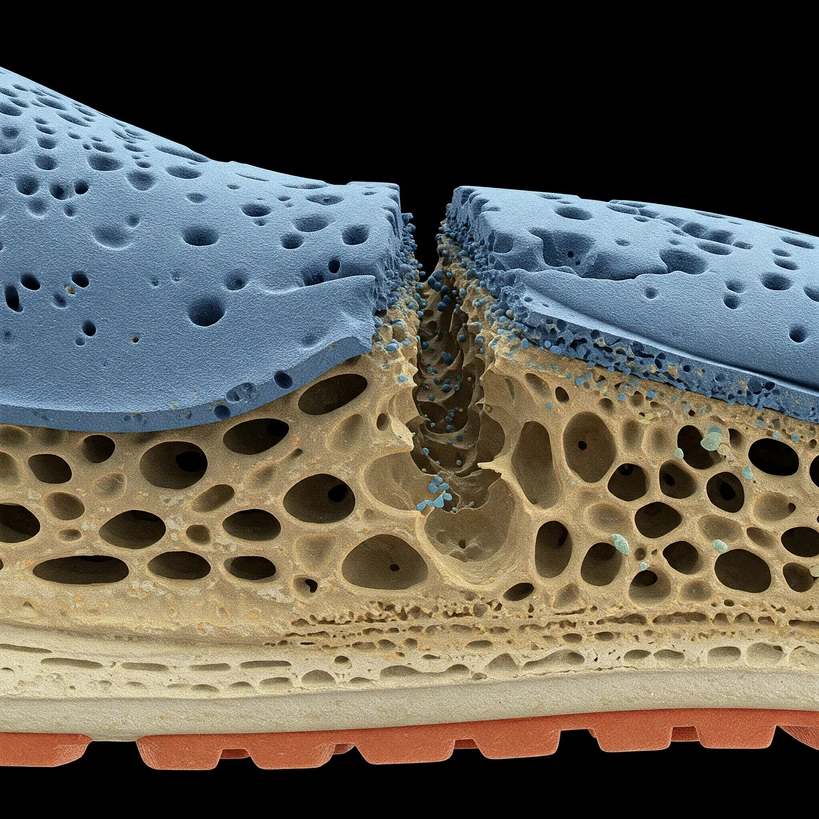

Think of midsole foam like a complex network of tiny, gas-filled cells or bubbles. When you land, these cells compress to absorb impact and then rebound. However, repeated compression and decompression take their toll at both microscopic and macroscopic levels.

- Microstructural Changes: At a cellular level, particularly in traditional EVA (Ethylene Vinyl Acetate) foams that have been studied extensively, researchers observe distinct changes over time. The cell walls can wrinkle, buckle, flatten, and even rupture under repeated stress. Micro-tears can form, and the foam structure can permanently compress, losing some of its air content and becoming denser. It’s like millions of tiny balloons slowly deflating and losing their bounce. Early research using electron microscopy visualized this damage, showing clear signs of cell wall buckling and tearing after hundreds of kilometers.

- Macroscopic Mechanical Changes: These microscopic changes manifest as alterations in the foam’s overall mechanical properties – the characteristics you might actually feel (or that can be measured in a lab):

- Increased Stiffness: Counterintuitively, as foam degrades, it often becomes stiffer and less flexible. The collapsed cell structure offers more resistance to compression. Studies have measured significant increases in midsole stiffness after simulated or real-world wear, sometimes by over 20% or even 40% depending on the foam type and mileage.

- Decreased Cushioning/Shock Absorption: This is the most commonly perceived effect. As the foam cells collapse and lose their ability to effectively compress and rebound, the shoe’s capacity to attenuate impact forces diminishes. Seminal studies from the 1980s showed that shoes could lose over a third of their initial shock absorption capacity within the first 150 miles and potentially retain less than 60% after 500 miles in mechanical tests (though real-world wear by runners was slightly less severe). More recent studies consistently confirm this loss of cushioning over distance, although the rate varies.

- Reduced Energy Damping (Viscosity): The foam’s ability to dampen vibrations also decreases as it degrades.

- Altered Energy Return (Resilience): This is more complex. For traditional foams, the ability to “bounce back” and return energy often decreases with wear. However, modern high-energy return foams (like PEBA) have different properties, and how their energy return changes over time is a key area of ongoing research and debate, crucial for performance shoes. Some studies have found surprisingly little change in energy return for certain foams over specific distances, even while cushioning degraded, highlighting the complexity.

C. The Degradation Curve: Not a Straight Line Downhill

Importantly, running shoe midsole degradation isn’t typically a linear process. Evidence suggests that the rate of change is often faster in the initial stages of a shoe’s life. You might experience a more noticeable drop-off in cushioning or responsiveness during the first 100-150 miles (around 160-240 km) as the foam “breaks in” and undergoes initial compression set. After this initial period, the degradation rate may slow down, potentially reaching a plateau before further, more gradual decline later in the shoe’s life. Some research even suggests distinct phases of wear, with measurable shifts occurring early on, followed by stabilization, and then further changes after significant mileage (e.g., >600km).

D. Lab vs. Reality: A Note on Testing

Much of our understanding of running shoe wear science comes from laboratory tests where machines simulate running impacts. While valuable, these tests have limitations. They often involve continuous loading without the rest periods shoes get between runs, and the force profiles might not perfectly mimic human biomechanics. Some studies have shown that mechanical testing can overestimate the rate or extent of degradation compared to shoes worn by actual runners. Including rest periods in mechanical testing protocols seems to produce results closer to real-world wear, suggesting that foam might have some limited capacity to recover between runs, although this is also debated and material-dependent. This distinction is important – lab results provide insights, but real-world wear involves more variables.

III. Midsole Materials Deep Dive: Not All Foams Are Created Equal

If the midsole is the engine of the shoe, then the specific type of foam used is the engine’s design and material composition. It’s perhaps the single most significant factor influencing how a shoe feels, performs, and, crucially, how it ages. The running shoe wear science becomes much clearer when we understand the different characteristics of these materials. Let’s break down the main players:

A. The Workhorse: EVA (Ethylene Vinyl Acetate)

- What it is: For decades, EVA has been the go-to midsole material for the vast majority of running shoes. It’s a versatile foam created by copolymerizing ethylene and vinyl acetate.

- Pros: Lightweight, relatively inexpensive to produce, offers good initial cushioning and flexibility.

- Cons & Aging: EVA’s main drawback is its susceptibility to compression set – the tendency to permanently deform under repeated stress. As discussed, EVA cells collapse and don’t fully rebound over time. This leads to the classic symptoms of running shoe midsole degradation: the shoe feels flatter, firmer, and less protective. EVA is also quite sensitive to temperature, becoming noticeably firmer and less cushioned in cold weather.

- Evidence: Countless studies have documented EVA’s degradation patterns. Research confirms significant loss of cushioning properties after several hundred kilometers/miles and has visually documented the structural breakdown (flattened, buckled cells) associated with this loss.

- Variations: Shoe companies often use proprietary blends or processes to improve EVA’s durability and resilience (e.g., CMEVA – Compression Molded EVA, SPEVA, FlyteFoam which often incorporates other materials). These enhanced EVAs aim to mitigate the rapid breakdown of basic EVA.

B. The Durable Option: PU (Polyurethane)

- What it is: Polyurethane is another type of polymer foam used in midsoles, though often less common than EVA in standard running shoes (it’s frequently used in walkers or heavier stability shoes).

- Pros: Generally denser and more resistant to compression set than traditional EVA. This translates to better durability – PU midsoles tend to break down more slowly and maintain their cushioning properties for longer.

- Cons & Aging: PU is typically heavier and less bouncy or responsive than many modern EVAs or other advanced foams. Its aging process involves slower degradation, but it can still lose some properties over time. Interestingly, some research showed certain PU foams increasing in cushioning during the initial 200-300 km before potentially declining, highlighting variability even within this category. Energy return is often lower than EVA initially.

- Evidence: Comparative studies have generally shown PU midsoles retain their cushioning characteristics better than standard EVA over distances like 500 km.

C. The Bouncy Revolution: TPU (Thermoplastic Polyurethane – including E-TPU/Boost)

- What it is: TPU takes polyurethane’s durability and adds a significant twist, especially in its expanded form (E-TPU). The most famous example is Adidas’ Boost technology, created by fusing thousands of small, springy TPU pellets.

- Pros: The defining characteristic of E-TPU is its high energy return or “bounciness,” significantly higher than traditional EVA or PU. It’s also highly resistant to compression set, leading to excellent durability – it maintains its cushioning and bouncy feel for a long time. Furthermore, TPU is far less sensitive to temperature changes than EVA, performing consistently in both hot and cold conditions. Many runners find E-TPU midsoles exceptionally comfortable for high-mileage training.

- Cons & Aging: The main drawback of TPU, particularly E-TPU, is often its weight; it tends to be heavier than EVA and the newer PEBA foams. While structurally durable, the perception of its energy return might still diminish slightly over very long periods, though the cushioning loss is typically much slower than EVA.

- Evidence: Studies confirm the superior resilience (energy return) and temperature resistance of E-TPU compared to standard EVA. Its reputation for longevity is well-earned in the running community.

D. The Super Foam: PEBA (Polyether Block Amide – including Pebax/ZoomX etc.)

- What it is: PEBA (often trademarked as Pebax, and used in foams like Nike’s ZoomX) is the lightweight, high-energy-return foam that fueled the “super shoe” revolution starting around 2017. It’s a thermoplastic elastomer offering a unique combination of properties.

- Pros: Extremely lightweight, allowing for maximalist stack heights without weighing the shoe down. Exceptional energy return, often cited as being over 80% or even 87%, leading to documented improvements in running economy. Soft and compliant feel underfoot. Claims of better temperature resistance than EVA.

- Cons & Aging: This is where the running shoe midsole degradation story gets fascinating and contested. While PEBA offers incredible performance initially, questions linger about its long-term durability, especially concerning that performance edge.

- Evidence & The Durability Debate: (See next point)

E. The Durability Showdown & Contradictions: Performance Life vs. Structural Life

Comparing the durability of these foams isn’t straightforward because “durability” itself can mean different things, and the running shoe wear science presents a complex picture:

- Structural Durability (Resisting Breakdown): In terms of simply resisting permanent compression and cushioning loss, the general hierarchy often seems to be TPU > PU > Modern EVA Blends > PEBA ≈ Basic EVA. TPU and PU are champions of resisting compression set. PEBA, being very light and airy, is thought by some to be more susceptible to faster structural breakdown than TPU or even some robust EVAs, though specific formulations vary wildly. Some microscopic analyses suggest PEBA’s lighter structure might be prone to faster fatigue kinetics compared to denser foams.

- Performance Durability (Maintaining ‘Pop’): This is where PEBA’s story gets complicated. While structurally it might hold up reasonably well (though perhaps not as well as TPU), studies suggest its performance benefits (specifically the energy return contributing to improved running economy) can diminish relatively quickly. One key study found that PEBA-based shoes lost their significant running economy advantage over EVA-based shoes after just 450 km (approx. 280 miles). The PEBA shoes showed a measurable increase in the energetic cost of running, while the EVA shoes did not. This suggests that while the PEBA shoe might still feel cushioned, its “super” properties fade faster than its basic structure degrades. Anecdotal reports from runners often echo this sentiment – super shoes feel fastest in their early life.

- Formulations are Paramount: It’s crucial to reiterate that these are general categories. A specific company’s high-end EVA blend might outperform a basic PEBA formulation in some aspects, or vice-versa. Additives, density, molding processes, and proprietary secrets mean huge variability exists within each foam type. Recent research comparing different commercial foams highlighted significant differences in fatigue behavior linked directly to their microstructure (porosity, cell wall structure, fillers), reinforcing that the specific recipe matters immensely.

- The Takeaway: There’s often a trade-off.

- PEBA: Offers peak performance and low weight initially, but that performance edge might have a shorter lifespan. Best suited for race day or key workouts where maximum benefit is desired.

- TPU: Offers excellent structural durability and consistent feel over many miles, making it ideal for high-mileage trainers, but comes with a weight penalty and lower peak energy return than PEBA.

- EVA/Blends: Occupy a middle ground, with variable durability depending on the specific formulation. Modern blends offer a good balance for daily training but will likely experience more noticeable cushioning loss over time compared to TPU.

- PU: Generally reserved for situations where maximum durability outweighs weight or responsiveness concerns.

Understanding these material differences is fundamental to interpreting running shoe midsole degradation and moving beyond simple mileage rules. A 300-mile PEBA shoe might have lost more performance than a 300-mile TPU shoe, even if both still feel adequately cushioned.

IV. Debunking the Mileage Myth: Why “300-500 Miles” is Flawed Advice

We’ve alluded to it several times, but now it’s time to directly confront the elephant in the running store: the ubiquitous “300-500 mile” (or 500-800 km) replacement guideline. While well-intentioned, relying on this arbitrary range as a definitive rule for shoe retirement is outdated, overly simplistic, and not supported by robust running shoe replacement evidence.

A. The Origin Story: Where Did It Come From?

The exact genesis is murky, but the guideline likely gained traction partly due to early running shoe wear science studies, particularly influential research from the mid-1980s (like the Cook et al. study often cited). These studies, primarily using mechanical testing on the running shoes of that era (which were predominantly basic EVA), observed significant decreases in shock absorption capabilities within that 300-500 mile range. For instance, finding that shoes retained less than 60% of their initial capacity after 250-500 miles in machine tests was a notable result. It’s plausible that these findings, disseminated through running media and industry channels, solidified into the easy-to-remember rule we hear today.

B. Why It Fails Today: A Critical Look at the Flaws

Decades later, applying this same rigid guideline ignores massive advancements in shoe technology and our understanding of biomechanics. Here’s why it’s flawed:

- Lack of Universal Scientific Backing: Despite its popularity, there’s no strong scientific consensus validating this specific mileage range as a universal trigger point for replacement. Research consistently highlights the high variability in shoe lifespan. The running shoe replacement evidence points towards complexity, not a simple number.

- Outdated Technology Benchmark: The early studies were based on shoe technology from the 1980s. Midsole foams, construction methods, and materials have evolved dramatically since then. Basic EVA from that era likely degrades differently and perhaps more rapidly than many modern EVA blends, TPU, or PEBA foams. Furthermore, some early testing methodologies might have overestimated wear compared to real-world running.

- Ignores Material Diversity: This is perhaps the biggest flaw. As detailed in the previous section, different midsole materials age very differently. A rule based on basic EVA cannot possibly apply accurately to a durable TPU shoe or a high-performance PEBA shoe. We now know that PEBA’s performance benefits might diminish well before the 300-mile mark, something the old rule completely misses. Conversely, a robust TPU shoe might feel great well past 500 miles.

- Disregards Influencing Factors: The mileage myth completely ignores the multitude of factors affecting running shoe life beyond distance. It doesn’t account for runner weight, individual biomechanics, running surfaces, environmental conditions, or shoe design specifics (like stack height or outsole coverage). Two runners wearing the exact same shoe model can experience vastly different lifespans based on these variables.

- Focuses Only on One Metric (Shock Absorption): The early research underpinning the guideline primarily focused on the loss of shock absorption. While important, it’s only one aspect of shoe function. Changes in stability, energy return, flexibility, or even upper integrity also contribute to a shoe’s end-of-life, and these may degrade at different rates.

C. What the Mileage Rule Might Indicate (If Anything)

At best, the 300-500 mile range might represent a general ballpark where some runners, using certain types of shoes (perhaps more traditional EVA trainers), might start to experience significant mechanical degradation in properties like cushioning. However, it should be viewed as a potential alert to start paying closer attention, not as a definitive expiration date. For many modern shoes and many runners, it’s simply not an accurate or helpful metric when used in isolation.

D. The Evidence Points Elsewhere

Modern running shoe wear science and longitudinal studies tracking changes over distance paint a picture of variability. We see significant pressure changes recorded after 700km in one study, running economy shifts measured by 450km in PEBA shoes in another, and substantial stiffness changes noted after 660km simulations. These objective changes occur across a wide spectrum of distances, not neatly within the confines of the old rule. Relying on the myth prevents runners from understanding the true, individualized lifespan of their specific shoes.

V. The Real Determinants: What Actually Dictates Running Shoe Lifespan?

If mileage alone isn’t the answer, what truly determines how long your running shoes will last? The reality is that shoe lifespan is a complex equation influenced by a dynamic interplay of factors related to you, your running environment, and the shoes themselves. Understanding these factors affecting running shoe life is key to developing realistic expectations and making informed replacement decisions.

A. Runner-Specific Variables: It Starts With You

- Body Weight: It’s simple physics – heavier runners exert greater forces on their shoes with every footstrike. While direct experimental studies quantifying the exact impact of weight on the rate of midsole degradation per mile are somewhat limited in the readily available literature (though weight is often controlled for or considered in research protocols), it’s a strong theoretical factor. Logically, higher impact forces should lead to faster material fatigue and breakdown of the midsole foam structure. Anecdotally, heavier runners often report shorter shoe lifespans.

- Biomechanics: How you run significantly impacts where and how stress is applied to your shoes. Key factors include:

- Footstrike Pattern: Heel strikers will wear down the heel cushioning and outsole rubber in that area more quickly than midfoot or forefoot strikers, who will stress different zones.

- Pronation: Runners who overpronate (foot rolls inward excessively) or supinate (foot rolls outward) may place uneven stress on the medial (inner) or lateral (outer) sides of the midsole, leading to faster breakdown in those areas.

- Stride Characteristics: Step length, cadence (steps per minute), and ground contact time influence the duration and nature of the forces applied.

- Loading Rate: How quickly force is applied upon impact (vertical loading rate) can also influence material fatigue.

- Gait Asymmetries: Differences between your left and right leg mechanics can lead to uneven wear between your shoes.

B. External Factors: Where and How You Run

- Running Surface: The type of terrain you run on plays a role.

- Hard Surfaces (Asphalt, Concrete): These surfaces offer less natural shock absorption, potentially increasing the impact forces the shoe’s midsole needs to handle. This is generally assumed to accelerate running shoe midsole degradation, although some research on force transmission shows complex interactions and potential runner compensations. Harder surfaces also typically cause faster outsole rubber abrasion.

- Softer Surfaces (Trails, Grass, Track): These surfaces provide more natural cushioning, potentially reducing the stress on the midsole foam and extending its life. However, trails can introduce other wear factors like abrasion from rocks, mud, and uneven terrain stressing the upper and outsole differently.

- Mileage Accumulation Pattern: It’s not just total mileage, but how you accumulate it.

- Frequency and Distance: Running long distances frequently without adequate rest days for your shoes might accelerate breakdown, though the evidence on foam recovery time is mixed. Some early studies found minimal benefit from 24-48 hour rest periods for EVA, while newer research suggests rest can allow some measurable recovery in mechanically aged foams. Some experts theorize foam needs more than 24 hours to fully “rebound.”

- Shoe Rotation: Using two or more pairs of shoes and alternating them is frequently recommended. This allows each pair more time to recover between runs (potentially allowing foam to decompress more fully) and varies the stresses on your feet and body. Studies have shown runners who rotate shoes have a lower risk of running-related injuries. While this doesn’t definitively prove it extends the absolute lifespan of the foam in terms of material science, it’s a practical strategy often linked to better shoe longevity and potentially lower injury risk.

- Environmental Conditions:

- Temperature: As mentioned, EVA foam is notoriously sensitive to cold, becoming significantly stiffer and less protective. TPU and PEBA are generally more stable across temperatures. Running consistently in very cold conditions could impact the feel and potentially the long-term wear of EVA shoes. Extreme heat (like leaving shoes in a hot car) can also potentially degrade foam and adhesives over time.

- Moisture: Running frequently in wet conditions or storing shoes damp can potentially affect the integrity of glues and materials over the long term. Proper drying is important.

C. Shoe Design Features: The Shoe Itself

- Midsole Material & Formulation: (The King Factor!) As extensively discussed in Section III, the type of foam (EVA, PU, TPU, PEBA) and its specific proprietary blend, density, and manufacturing process is the primary determinant of inherent durability and degradation pattern.

- Midsole Stack Height (Thickness): Thicker midsoles generally provide more initial cushioning simply because there’s more material to compress. However, thickness alone doesn’t guarantee durability. The quality of the foam matters more. Extremely thick midsoles (maximalist shoes) might even introduce stability challenges for some runners or affect proprioception (your sense of foot position). There might be an optimal thickness range for balancing cushioning and other factors, though this is debated, especially with the rise of high-stack super shoes. How thickness interacts precisely with fatigue life is complex.

- Outsole Design: The amount and type of rubber on the outsole significantly impacts overall shoe life. Durable carbon rubber in high-wear areas protects the underlying midsole foam from abrasion. Shoes with extensive exposed midsole foam will inevitably wear down faster in those areas.

- Structural Elements: Features like internal shanks, truss systems, rigid heel counters, or stability posts can influence the shoe’s mechanics and potentially how forces are distributed through the midsole, which could subtly affect wear patterns. The effect of carbon plates on foam durability specifically is still an area of research; their primary documented effects are on stiffness and running economy, though they undoubtedly alter shoe mechanics.

D. The Crucial Interplay

It’s vital to understand that these factors affecting running shoe life don’t operate in isolation. They interact dynamically. Imagine:

- Runner A: 190 lbs, heavy heel striker, runs 40 miles/week mostly on asphalt in a lightweight PEBA racing shoe.

- Runner B: 130 lbs, midfoot striker, runs 25 miles/week mostly on trails in a durable TPU training shoe.

Runner A is subjecting their shoes to significantly higher forces, on a harder surface, potentially concentrating wear in the heel, using a foam known for potentially faster performance degradation. Runner B has lower impact forces, runs on a softer surface, and uses a more structurally durable foam. It’s almost certain that Runner A’s shoes will reach the end of their functional life (especially performance life) much sooner than Runner B’s, even if they ran the exact same total mileage.

This intricate interplay underscores why a simple mileage rule is inadequate. Assessing shoe lifespan requires considering the entire context – the runner, the environment, and the shoe itself.

VI. Feeling the Difference: How Worn Shoes Change Your Run (Biomechanical Effects)

So, we know shoes break down. But does this running shoe midsole degradation actually change how you run? The answer, according to running shoe wear science, is yes – although the changes are often more subtle and complex than you might expect, thanks largely to your body’s remarkable ability to adapt.

A. Ground Reaction Forces (GRF) & Loading Rates: The Impact Question

Logically, you’d assume that as cushioning diminishes, the impact forces transmitted to your body would increase. The evidence here is somewhat mixed:

- Potential Increases: Some studies have measured increases in impact-related variables after significant shoe wear. For example, research has documented increases in Peak Tibial Acceleration (the shock experienced by your shin bone) and Vertical Force Loading Rate (how quickly the peak impact force is reached) after several hundred kilometers of running. This aligns with the idea that less effective cushioning allows forces to transmit more sharply.

- Adaptation & Compensation: However, other studies measuring the overall peak vertical ground reaction force haven’t always found significant increases even after considerable mileage. This suggests that runners might subconsciously alter their stride (e.g., landing slightly softer, adjusting joint stiffness) to compensate for the perceived or actual loss of cushioning, thereby keeping peak forces relatively stable. The general relationship between shoe cushioning and actual impact forces is complex even with new shoes, and this complexity extends to worn shoes.

B. Kinematics: How Your Movement Patterns Shift

Do worn shoes make you run dramatically differently? Usually not. The changes in joint angles and movement patterns (kinematics) tend to be subtle:

- Minor Adjustments: Studies have observed slight changes like increased stance time (foot spends longer on the ground), slightly reduced forward trunk lean, or small alterations in ankle motion (e.g., decreased peak dorsiflexion) after accumulating mileage (e.g., 200 miles / 320 km).

- Stability in Major Joints: Interestingly, major kinematic variables like peak knee and hip flexion angles often remain remarkably consistent even after significant shoe wear in some studies.

- Early Changes in Control?: Some research suggests that parameters related to foot motion control, like pronation velocity or magnitude, might change most significantly during the initial wear period (e.g., first 100 km) and then stabilize.

- The Body’s Priority: This suggests the neuromuscular system works hard to maintain overall preferred movement pathways, making subtle adjustments at the foot and ankle rather than drastically altering the entire kinematic chain just because the shoe is aging.

C. Plantar Pressure Distribution: Where the Load Goes

As specific areas of the midsole foam fatigue and compress, the way pressure is distributed across the bottom of your foot can change:

- Load Shifting: Research has shown measurable shifts in plantar pressure patterns with shoe wear. One study found a significant increase in peak pressure under the midfoot after 700 km, while pressure changes under the heel and forefoot were less pronounced. Earlier work reported even larger (up to 100%) increases in peak pressure after 500 km.

- Indication of Fatigue: This redistribution likely occurs as certain fatigued zones of the foam become less effective at cushioning, forcing adjacent areas or different structures within the foot to bear more load.

D. Muscle Activation: Your Muscles Working Differently

Your muscles might also subtly change their firing patterns to accommodate aging shoes:

- Compensatory Activity: Researchers have observed increased activation in certain muscles (like the vastus lateralis, part of the quadriceps) when running in mechanically aged shoes compared to new ones. This likely represents a compensatory strategy – the muscles working slightly harder or differently to control motion or absorb shock that the degraded shoe is no longer managing as effectively.

E. The Overarching Theme: Adaptation

While measurable biomechanical changes do occur as shoes wear out, the key takeaway is the power of neuromuscular adaptation. Your body isn’t a passive system; it actively adjusts and compensates for the gradual changes in footwear properties. This remarkable adaptive capacity explains why:

- Changes are often subtle rather than dramatic.

- Major kinematic patterns tend to be preserved.

- Runners might not consciously perceive significant differences until degradation is quite advanced.

Understanding this adaptation is crucial when considering the potential link between worn shoes and injury risk.

VII. The Elephant in the Room: Do Worn-Out Shoes Cause Injuries?

This is one of the most frequently asked questions, driven by a seemingly logical assumption: worn-out shoes provide less cushioning and support, leading to increased stress on the body, which must surely increase injury risk. It makes intuitive sense. However, when we look closely at the running shoe replacement evidence, the connection between gradual running shoe midsole degradation and the incidence of running-related injuries (RRIs) is surprisingly weak and inconsistent.

A. The Theoretical Link

The theory posits that as midsole foam breaks down:

- Reduced Shock Absorption: Leads to higher impact forces and loading rates being transmitted to the bones, joints, and soft tissues. Higher loading rates, in particular, have been associated with stress injuries like stress fractures.

- Altered Mechanics/Stability: Changes in foam properties could affect foot motion control (e.g., pronation) or lead to uneven pressure distribution, potentially overloading specific tissues (like tendons or fascia).

B. What Does the Scientific Evidence Actually Show?

Despite the plausible theory, robust scientific studies have struggled to establish a clear, direct, causal link between running in shoes past a certain mileage or level of degradation and a significantly higher risk of injury:

- Lack of Strong, Consistent Evidence: Systematic reviews and individual studies often conclude that there is limited or inconclusive evidence to support this direct link. While some observational studies might find correlations (e.g., runners reporting older shoes alongside injuries), these don’t prove causation. Many other factors confound the issue.

- Conflicting Findings: Some studies have found no significant difference in injury rates between runners using shoes with different cushioning properties (relevant because wear primarily affects cushioning). Research observing minimal biomechanical changes with wear also casts doubt on a strong injury link. One older study even noted improved foot control parameters as cushioning decreased, suggesting not all changes are detrimental. Another study tracking university runners found measurable midsole degradation but couldn’t correlate it with injury or pain scores over a 4-week period.

- The Complexity of RRI: Running injuries are notoriously multifactorial. Training load (volume, intensity, changes), individual anatomy, biomechanics (independent of shoes), strength, flexibility, fatigue, recovery, and even genetics play significant roles. Isolating the specific contribution of shoe wear within this complex web is incredibly difficult.

C. Why Isn’t the Link Clearer? The Power of Adaptation Revisited

The lack of strong evidence, despite measurable shoe degradation, likely comes back to the body’s impressive adaptive capabilities:

- Effective Compensation: As discussed previously, runners subconsciously adjust their stride and muscle activation to compensate for gradual changes in their shoes. This adaptation can effectively mitigate potentially harmful increases in tissue stress, at least up to a certain point.

- Gradual Change: Because shoe degradation is usually a slow, incremental process, the body has time to adapt. Injuries related to footwear might be more likely when there’s an abrupt change (like switching to a drastically different shoe type) rather than gradual wear.

- Potential Threshold Effect: It’s possible that injury risk doesn’t increase linearly with shoe wear. Instead, risk might only rise significantly if:

- Degradation becomes extremely severe, overwhelming the body’s adaptive capacity.

- The runner’s adaptive capacity is compromised (e.g., by fatigue, rapid increase in training load).

- A runner has a pre-existing vulnerability where even subtle changes in load due to shoe wear are enough to tip a specific tissue over its tolerance threshold.

D. The Shoe Rotation Clue

One intriguing piece of the puzzle comes from studies on shoe rotation. Research found that runners who regularly alternated between two or more different pairs of running shoes had a significantly lower risk of RRI compared to those who used only one pair. While this doesn’t directly prove that wear in the single pair caused injuries, it strongly suggests that varying the load patterns on the body (by using different shoes, which likely also means each pair accumulates less wear in a given period) is beneficial for injury prevention.

E. The Takeaway: Nuance is Key

Based on current running shoe replacement evidence, we cannot definitively state that running in moderately worn shoes automatically increases your injury risk. The link is complex, likely non-linear, and heavily influenced by individual adaptation and myriad other factors. This doesn’t mean you should run your shoes into the ground – excessive wear certainly removes the protective features the shoe was designed to offer. However, panicking solely based on mileage is unwarranted. A more nuanced approach focusing on overall shoe condition and how your body feels is more appropriate.

VIII. Beyond Mileage: Practical Ways to Assess Your Running Shoes

If mileage is a flawed metric and the injury link is weak, how do you determine when it’s time for a new pair? The most effective strategy involves moving beyond any single indicator and adopting a multi-pronged approach, combining careful observation with an awareness of how your shoes feel and perform, all viewed through the lens of the running shoe wear science we’ve discussed. This section provides practical guidance on how to assess running shoe wear.

A. The Unreliable Narrator: Why “Feel” Alone Isn’t Enough

Before diving into assessment methods, let’s address subjective perception. While how a shoe feels is important for comfort, research consistently shows that runners are generally poor judges of objective cushioning loss.

- Perception Lags Behind Reality: Studies have demonstrated significant, measurable decreases in midsole cushioning (e.g., 16-33% loss) after several hundred miles, yet runners in those same studies often reported no significant change in perceived cushioning even at much higher mileages (e.g., 640 km / 400 miles). It seems our sensory perception might only detect changes once they become quite substantial (perhaps >10% objective change) or if the degradation is localized to a specific, sensitive area (like increased pressure under the midfoot correlating with poorer perceived cushioning there).

- The Risk: Relying solely on subjective “feel” means you might continue running in shoes whose protective properties have significantly degraded long before you consciously notice it.

B. A Multi-Factor Assessment Strategy:

Instead of relying on one flawed metric, use a combination of these checks:

- Visual Inspection: Become a Shoe Detective

- Outsole Wear: Examine the rubber tread. Are there areas worn completely smooth, especially in key landing or push-off zones? Is the wear pattern highly asymmetrical between the left and right shoe? Excessive or uneven outsole wear can indicate the shoe’s geometry is compromised and exposes the softer midsole to faster abrasion.

- Midsole Creasing & Compression: Look closely at the midsole foam, particularly on the sides. Are there deep, permanent compression wrinkles or creases, especially under the heel or forefoot? Does the foam look visibly compressed or “packed down” compared to when it was new? (Comparing to a photo of the shoes when new, or to an identical new pair, is very helpful here).

- Midsole Deformation: Place the shoes on a flat surface. Do they sit level, or do they lean noticeably to one side (indicating uneven midsole collapse)? Press down on the heel counter – does the shoe deform excessively?

- Upper Integrity: Check the fabric upper for significant rips, tears, or holes, especially around the toe box or where the upper meets the midsole. Is the heel counter (the stiff part around your heel) still firm, or has it become soft and easily collapsible? A compromised upper affects support and lockdown.

- Flexibility & Torsion: Gently try to bend the shoe at the forefoot – does it feel significantly easier or “floppier” than when new? Gently try to twist the shoe (torsion) – excessive twisting might indicate a breakdown in structural integrity, though this varies greatly by shoe design.

- Subjective Feel (Used Critically and in Context):

- Loss of Responsiveness: Does the shoe feel “flat,” “dead,” or lacking the “pop” or bounce it once had? This is often one of the first subjectively noticeable signs, especially in performance-oriented shoes.

- Reduced Protection: Do you feel more of the ground impact than before? Do your legs feel unusually beat up or fatigued after runs in these specific shoes compared to others?

- New Aches & Pains: This requires extreme caution. If you develop new aches or pains (e.g., in your shins, knees, feet) that seem to consistently appear only when wearing a specific older pair of shoes, and you haven’t made significant changes to your training load or routine, the shoes could be a contributing factor. However, always consider training errors (too much, too soon, too fast) as the primary suspect for new pains before blaming the shoes.

- Mileage Tracking (As ONE Data Point, Not the Rule):

- Keep a Log: Use a running app (Strava, Garmin Connect, etc.), spreadsheet, or notebook to track the mileage on each pair of shoes.

- Use as an Alert: Don’t set a hard retirement number. Instead, use mileage as a reminder. When a pair approaches a certain range (which might be 300 miles for a lightweight racer, but 500+ for a durable trainer, based on your experience and the factors discussed), start performing the visual and subjective checks more diligently.

- Adjust Expectations: Learn how different types of shoes tend to last for you. Lightweight racing flats or PEBA super shoes will likely have a shorter functional lifespan (especially performance life) than durable daily trainers with TPU or robust EVA midsoles. Factor in your weight, running surfaces, etc.

- Performance Changes (Especially for Super Shoes):

- If you use high-performance shoes (typically PEBA-based), pay attention to perceived performance. As research suggests their running economy benefits can fade relatively quickly, you might notice runs feeling slightly harder for the same pace, or the shoe losing its propulsive feeling, even if it still feels cushioned.

C. Putting It All Together: Informed Decision-Making

There’s no perfect formula for how to assess running shoe wear. The best approach is to synthesize information from all these areas. If a shoe has high mileage (for its type and your use), shows significant visual signs of wear (heavy outsole abrasion, deep midsole creases), and feels noticeably less protective or responsive, it’s likely time to retire it from running duties (it might still be fine for walking!). Don’t wait for catastrophic failure or rely solely on the calendar or the odometer.

IX. Pro Tips: Extending the Life of Your Running Shoes

While running shoe midsole degradation is inevitable, you can take steps to maximize the functional lifespan of your footwear and potentially delay replacement:

- Rotate Your Shoes: This is arguably the most effective strategy. Having at least two pairs of running shoes and alternating them allows the midsole foam more time (ideally 24-48 hours) to decompress and recover between runs. While the extent of foam recovery is debated, this practice also varies the stresses on your feet and body, which, as noted, is linked to lower injury risk.

- Use Them Only for Running: Resist the temptation to wear your running shoes for walking, errands, gym workouts, or casual wear. Different activities place different stresses on the shoes, and unnecessary wear and tear will shorten their running-specific life.

- Clean Properly: Dirt and grit can be abrasive. Clean your shoes when they get dirty, but avoid the washing machine and dryer. Machine washing can damage materials and glues, and the heat from dryers is detrimental to midsole foam. Use a soft brush, mild soap, and cold water. Remove insoles to clean separately if needed.

- Air Dry Naturally: Stuff wet shoes with newspaper or paper towels to absorb moisture and let them air dry completely away from direct heat sources (like radiators or direct sunlight).

- Store Appropriately: Avoid leaving shoes in extreme temperatures for extended periods (e.g., hot car trunks in summer, unheated garages in freezing winters), as this can potentially affect foam properties and adhesives over time.

- Untie Your Laces: Don’t crush the heel counter by forcing your foot in or slipping the shoes off while tied. Untie and retie properly to maintain the upper’s structure and support.

Following these simple care habits won’t magically make your shoes last forever, but they can help ensure you get the most functional mileage out of each pair.

X. The Horizon: Future of Running Shoe Durability & Research

The running shoe wear science is a constantly evolving field. As materials technology advances and our understanding of biomechanics deepens, we can expect further developments:

- New Materials & Blends: Shoe companies are continuously experimenting with new foam formulations, additives, and composite structures (like incorporating plates or rods) to optimize the balance between cushioning, energy return, weight, and durability. We’ll likely see even more sophisticated midsole materials emerge.

- Standardized Durability Testing: There’s a need for more standardized and sophisticated testing protocols that better replicate real-world running conditions and assess not just cushioning loss but also changes in energy return, stability, and other performance characteristics over time. This would allow for more reliable comparisons between different shoes.

- Understanding Adaptation & Injury: Further research is needed to better understand the complex interplay between shoe wear, biomechanical adaptation, training load, and injury risk. Identifying potential thresholds or specific biomechanical changes linked to increased risk remains a key challenge.

- Long-Term Wear Studies: More longitudinal studies tracking the effects of wear on modern shoe types (especially super shoes and high-stack trainers) beyond the commonly studied 500-800km range are needed to fully understand their complete lifecycle.

As researchers continue to unravel the complexities of running shoe midsole degradation and its effects, runners will hopefully benefit from even better footwear and more evidence-based guidance in the future.

XI. Conclusion: Finding Your Shoe Replacement Sweet Spot

Navigating the world of running shoe replacement can feel overwhelming, especially with conflicting advice and the allure of ever-newer technology. However, by grounding ourselves in the running shoe wear science, we can move beyond simplistic mileage rules and make more informed, individualized decisions.

Let’s recap the key takeaways from our deep dive:

- Midsole Degradation is Real: Running shoe midsoles undergo measurable structural and mechanical changes with cumulative mileage, primarily impacting cushioning, stiffness, and energy return.

- The Mileage Myth is Busted: The “300-500 mile” rule lacks universal scientific support, ignores material diversity, and fails to account for the numerous individual and environmental factors affecting running shoe life.

- Materials Matter, But It’s Complicated: Foam type (EVA, PU, TPU, PEBA) is a primary driver of durability, but specific formulations vary greatly. There’s often a trade-off between peak performance longevity and structural longevity.

- Lifespan is Highly Individual: Your weight, biomechanics, running surfaces, mileage patterns, and shoe design all interact to determine how quickly your shoes wear out.

- Adaptation is Key: Your body actively compensates for gradual shoe wear, meaning biomechanical changes are often subtle.

- The Injury Link is Weak: Current running shoe replacement evidence does not strongly support a direct causal link between moderate shoe wear and increased injury risk for most runners, likely due to adaptation and the multifactorial nature of injuries.

- Assessment Requires Multiple Indicators: Don’t rely on mileage or subjective feel alone. Use a combination of visual inspection, critical assessment of feel/performance, and mileage tracking as a guide to understand how to assess running shoe wear.

Ultimately, there is no single magic number or foolproof sign that signals the absolute end of a running shoe’s life. It’s a continuum, influenced by a complex web of factors. By understanding the principles of running shoe midsole degradation, recognizing the limitations of old guidelines, and learning to observe your shoes and listen intelligently to your body, you can find your replacement sweet spot. This knowledge empowers you to ensure your footwear is supporting your running goals safely and effectively, mile after mile.

Share your shoe assessment tips or experiences in the comments below!

(Disclaimer: This blog post provides information based on scientific analysis of running shoe wear. It is not intended as medical advice. Consult with a healthcare professional for any injury concerns.)

❓ Frequently Asked Questions

👟 What is midsole degradation in running shoes?

📏 How many miles do midsoles typically last?

🧪 What causes running shoe midsoles to break down?

🏃 Does midsole degradation affect performance?

⚖️ Does runner weight impact midsole lifespan?

💡 Can I feel midsole degradation happening?

📷 What visual signs show midsole wear?

🔁 Is rotating running shoes helpful?

🧽 Should I clean my running shoes regularly?

🔥 Does temperature affect midsole durability?

🔬 Which foam type lasts the longest?

❗ Are worn-out shoes dangerous?

📉 Does cushioning loss happen linearly?

🔎 How can I test if a shoe is still functional?

📚 Why is the “300-500 mile” rule flawed?

🛠️ Can I repair a worn midsole?

🌧️ Do wet conditions harm midsoles?

🧠 Does the body adapt to worn midsoles?

📊 Are lab tests reliable for midsole wear?

🎯 When should I replace my running shoes?

🔗 Further Reading

- 🔬 The Effect of Midsole Hardness on Running Mechanics and Injury Risk – ResearchGate

- 🧪 Running shoe cushioning properties and biomechanical adaptations – PubMed

- 👣 Longitudinal midsole stiffness changes and injury risk in runners – SAGE Journals

- 📏 Running shoe wear and performance loss: Evidence from mechanical testing – NCBI

- 🧼 How to Clean Running Shoes Properly – Runner’s World

🧠 Midsole Degradation Knowledge Quiz

- What is the primary function of a shoe midsole?

- Which foam type is known for the longest durability?

- How many miles does EVA foam typically last?

- True or False: Runners can always feel midsole breakdown.

- What’s a clear sign that a shoe’s midsole is degrading?

✅ Quiz Answers

- To provide cushioning and energy return during running.

- TPU (e.g., Adidas Boost) or PU foams are known for durability.

- Approximately 300–500 miles, depending on conditions.

- False. Many runners don’t notice cushioning loss until it’s severe.

- Visible creasing or flattening of the foam, especially under the heel.

📣 Share Your Score

Impressed by your knowledge? Share your result and help others learn about running shoe science!

🏁 Final Thoughts

Your running shoes are more than just gear — they’re the interface between your body and every step you take. Understanding midsole degradation helps you run smarter, avoid overuse injuries, and get the most out of your shoes. Whether you’re logging your first 50K or chasing a PR, cushioning science can be your hidden ally.

If you found this guide helpful, bookmark it and share it with a fellow runner who needs to check their shoes. Have a midsole-related experience or favorite foam? Drop a comment or email us — we love to hear from real runners like you!

Stay light on your feet, stay strong in your stride. 🏃♂️💨

🎥 Video Recommendation: The Truth about Midsole Foams

This insightful video dives deep into the materials used in running shoe midsoles and how they affect performance, durability, and feel. Featuring sports physiologist Geoff Burns, the discussion covers foam types like EVA, TPU, and PEBA, comparing their energy return, breakdown rates, and biomechanical influence over time.

If you’re curious about how midsole degradation really happens and what it means for your running experience, this video is a must-watch. It blends scientific analysis with practical advice for runners of all levels.

About the Author

Lost Pace is an ultramarathon runner, shoe-tester and the founder of umit.net. Based year-round in Türkiye’s rugged Kaçkar Mountains, he has logged 10,000 + km of technical trail running and completed multiple 50 K–100 K ultras.

Blending mountain grit with data, Lost analyses power (CP 300 W), HRV and nutrition to craft evidence-backed training plans. He has co-written 260 + long-form guides on footwear science, recovery and endurance nutrition, and is a regular beta-tester of AI-driven coaching tools.

When he isn’t chasing PRs or testing midsoles, you’ll find him sharing peer-reviewed research in plain English to help runners train smarter, stay healthier and finish stronger.

Ultrarunner · Data geek · Vegan athlete